FASTER ALERTS. SAFER OPERATIONS. FEWER INTERRUPTIONS.

Industrial Compliance and Safety AI

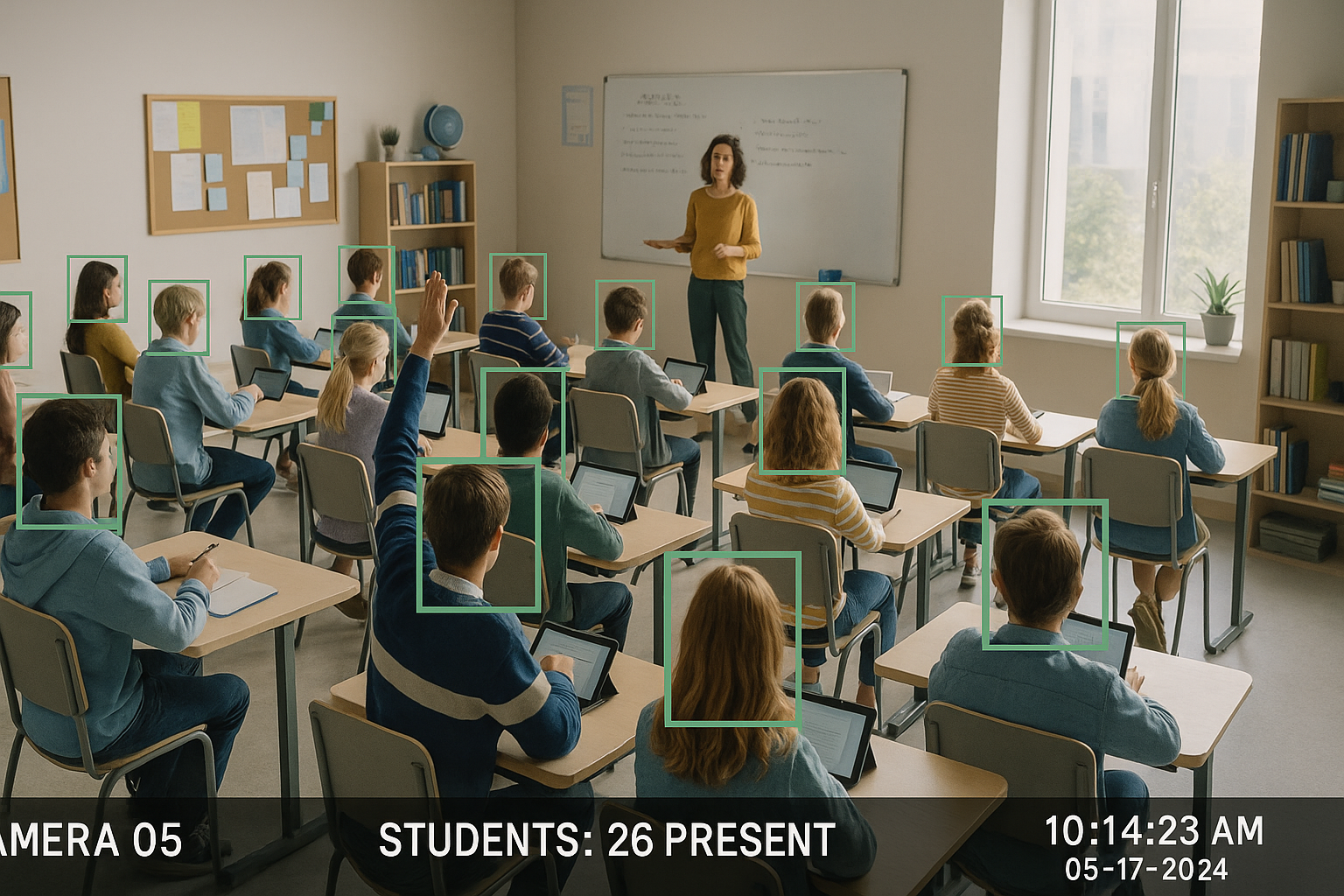

Cloud-based safety oversight that runs on the cameras you already have. It spots PPE misses, fall risks, environmental hazards, and unsafe load transfers in seconds—then sends focused alerts and auto-logs evidence. Operators can tailor it with simple photos (e.g., show what “proper PPE” looks like). SOC 2-aligned. No on-site GPU spend.

Manual patrols can’t cover every angle or shift. This platform enforces your safety rules consistently across lines, docks, crane bays, and yards—sending focused alerts and auto-logging visual evidence for audits and insurers. Because it’s cloud-first, you start fast on a predictable subscription instead of buying hardware, and you reduce injuries, fines, downtime, and hours spent watching screens.

WHAT IT DELIVERS

Fewer Incidents. Less Downtime. Proof on Demand.

CLOUD-FIRST INDUSTRIAL SAFETY

What Industrial Safety AI actually does

Industrial Safety AI connects to the cameras you already have and analyzes video in the cloud to prevent incidents. It spots missing PPE, flags fall risks, identifies environmental hazards, and watches load transfers for unsafe conditions—then sends focused alerts and logs visual evidence. Operators can tailor it with simple photo uploads that show “what right looks like,” so accuracy fits your site without ML expertise. SOC 2–aligned by design.

- Detects PPE misses, fall risks, environmental hazards, and unsafe load transfers in seconds.

- Operator-taught: upload photos to define correct gear, zones, and workflows—no data science required.

- Sends actionable alerts only; each event includes visual evidence for audits and reviews.

- Cloud deployment means no on-site GPUs and quick rollout across one or many facilities.

- SOC 2–aligned security with encryption, access controls, and audit logging.

How training Industrial Safety AIs works

Training is cloud-first and operator-led. Most sites start immediately with no special hardware. When you need site specifics, your team teaches the system with simple photos that show “what right looks like.” Every example and adjustment is recorded so you always know exactly what changed and why.

Minimal setup — works out of the box

General models recognize common PPE, fall-risk patterns, environmental cues, and load-transfer behaviors on day one. Connect your existing camera feeds, select the areas you care about, and the system begins detecting and logging events without a lengthy data-collection phase or a dedicated ML team.

Photo-based customization — teach it with a single image

Operators can upload a single photo to define expected PPE styles/colors, acceptable lift configurations, or “safe” zone conditions. Add a few more examples to cover lighting, angles, and unique equipment. Edits are self-serve and fast, so supervisors can refine results during normal operations—no data science required.

Auditable training log — every change captured

Each photo, rule, and threshold adjustment is time-stamped and attributed to a user, with before/after previews and notes. You can trace exactly what the AI was trained to recognize, export the history for reviews, and revert unwanted changes—supporting clear accountability and SOC 2–aligned evidence.

Personal Protective Equipment

What PPE* AI Does

Cloud-based oversight that catches missing or incorrect PPE in seconds, across the cameras you already have. You get fewer injuries and fines, consistent rule enforcement across shifts, and clean visual evidence for audits—without adding IT overhead. Operators can tailor “what right looks like” with simple photo uploads, and pricing stays predictable as you scale. SOC 2–aligned.

Real-time detection & alerts

Identifies missing hardhats, vests, glasses, gloves, or harnesses in live video and sends focused alerts to the right supervisors—so action happens before an incident.

Operator-taught PPE profiles

Upload a photo to define the exact gear style/colors your site requires; add a few examples for edge cases. No ML expertise needed, and changes are instantly visible.

Zone rules & context awareness

Apply different PPE rules by area (crane bays, docks, fabrication lines). The AI enforces the correct standard for each zone and shift, reducing false alarms.

Evidence & reporting

Every alert includes a visual snapshot and a timestamped record for audits and insurer reviews, with retention controls and access permissions aligned to SOC 2 practices.

Know exactly what your AI protection will cost, based on the hardware you choose.

Our pricing model is built around clarity. Because AI monitoring scales with VRAM requirements, you’ll know from the start how many feeds you can cover and what level of analysis each system can handle. There are no hidden usage fees, per-event costs, or unpredictable data charges.

Once your coverage goals are set, your costs stay consistent—month after month. Whether you’re monitoring 5 cameras or 50, the budget aligns directly with the GPU hardware you deploy, making it easy to forecast, expand, or optimize your system without financial guesswork.

SAFETY APPLICATIONS

Fall Prediction & Prevention AI

Cloud-based monitoring that spots risky postures, ladder/edge exposure, and near-falls in seconds using the cameras you already have. You cut recordables and stoppages, coach earlier, and keep clean visual evidence for reviews—without adding IT overhead. Operators can tailor “what safe looks like” with simple photo uploads. SOC 2–aligned.

Early risk detection

Identifies unsafe bends, slips, and loss-of-balance cues before a fall escalates—so supervisors can intervene in time.

Ladder & edge monitoring

Watches approaches to ladders, mezzanines, and platforms; flags unsafe climbs, missing tie-offs, and edge proximity.

Operator-taught site specifics

Upload photos to define acceptable postures, safe ladder use, and area rules for each zone or shift—no ML expertise required.

Evidence & trend reporting

Each alert includes a snapshot and timestamped record for audits and insurer reviews, plus simple trend views to target coaching.

Prove your data security

SOC 2 Compliance

- Monitors machinery, conveyors, valves, and lines for visible damage or abnormal behavior

- Sends instant alerts to maintenance and safety teams so they can act quickly

Real time danger monitoring

Equipment Damage

Our Equipment Damage Detection AI keeps a constant eye on your industrial site, spotting signs of broken, misaligned, or overheating equipment before they turn into safety incidents. It watches your existing cameras for leaks, sparks, unusual movement, or visible damage, then flags issues early so your team can lock out, tag out, and repair before someone gets hurt.

First Steps

Our pricing model is built around clarity. Because AI monitoring scales with VRAM requirements, you’ll know from the start how many feeds you can cover and what level of analysis each system can handle. There are no hidden usage fees, per-event costs, or unpredictable data charges.

Once your coverage goals are set, your costs stay consistent—month after month. Whether you’re monitoring 5 cameras or 50, the budget aligns directly with the GPU hardware you deploy, making it easy to forecast, expand, or optimize your security system without financial guesswork.